JUNENG consistently pursues machine improvement and technology innovation, ensuring that our customers own a stable production and consistent product quality. Our equipment can meet the non-stop production for 2-3 consecutive months, reducing the time and cost of maintenance. Achieving this, we enhance our system reliability from the following aspects.

JUNENG's production automation solution is one of the essential factors that make us stand out from our peers. The automated production line links different steps to increase productivity while optimizing resource allocation to save raw materials.

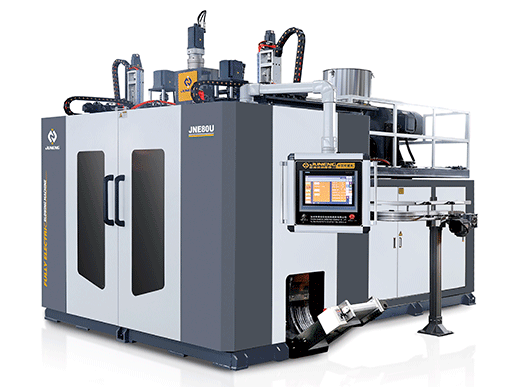

Our blow molding systems can be configured with an autoloader, robot arm, conveyor, bottle mouth cutter and other equipment, helping achieve an automated production process.

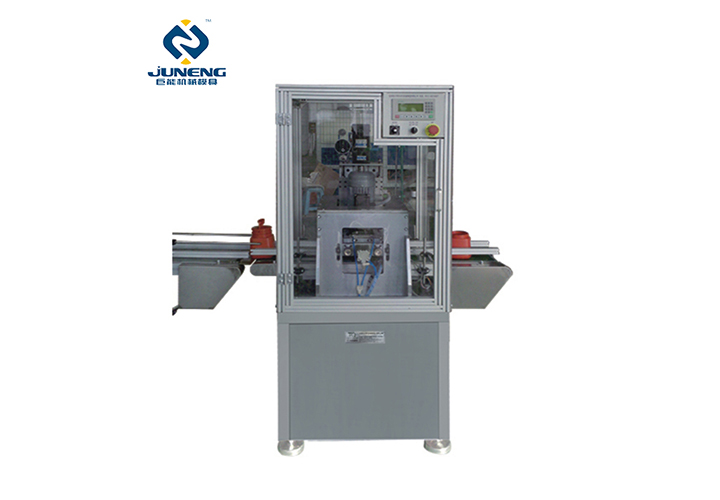

Also, we offer a wide range of downstream machines for fully automated production, such as in-mold labeling machines, packing machine, leakage detector and gasket machine. The automated downstream production line 2.0 is available now, see how we make your production efficient and economical.

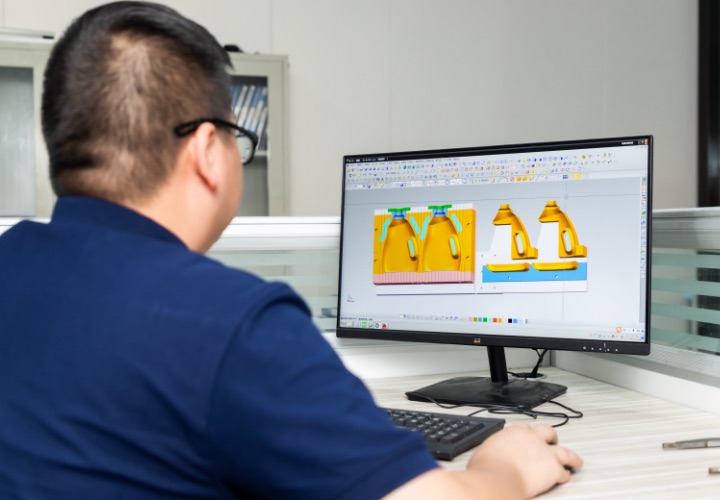

In order to provide you the best production solutions, we have established our own mold design department and production department. From raw materials screening to mold design to production, our seasoned engineers and technicians keep an eye on every detail, making the molds better fit our machines. When designing molds for complex-shaped products, we improve and innovate the mold structure, realizing auto deflashing. Besides, our self-designed water circuit makes cooling faster, bringing higher output and more consistent quality.

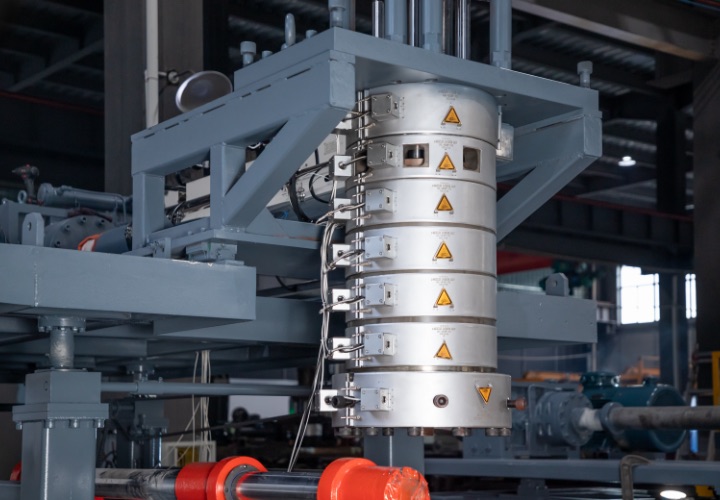

Extrusion heads are critical parts of the extrusion blow molding process. JUNENG selects premium raw material to ensure our die heads’ great performance. Our extrusion heads are made of 38CrMoAIA, 42 CrMov, 35CrMo and processed with heat treatment. This endows our die heads longer service life, reducing machine downtime and repair costs.

As a reliable manufacturer of extrusion blow molding machines, JUNENG never compromises on raw materials and components. All our components, such as PLC controllers, linear guides, oil pumps and servo motors, are selected from internationally renowned brands. We believe that better components bring better performance. Also, when manufacturing machine frames, we choose better iron and do more processing. This makes our frame more solid, reliable, smooth and durable. As a result, better operation stability is provided, and less subsequent maintenance is required.

The good barrier property of multi-layer packaging can preserve the product content appropriately and extend product shelf life. Also, multi-layer plastic containers are widely used in many industries, such as cosmetics and pharmaceuticals. With the technology of co-extrusion and multi-cavity, we produce multi-layer high-barrier vials efficiently and stably. To this end, our R&D team designs multi-layer spirals and die heads for different models, allowing a quick and even discharge. Multi-layer products cover from 30ml to 260L and are up to 8 layers.

With the increasing demand for economical and sustainable products, energy conservation has become a major pursuit of the extrusion blow molding industry. Energy-saving can not only bring cost-effectiveness to your production but also has important significance for environmental protection. Our All Electric Series can meet the requirements of economic and environmentally friendly production. Machines in All-Electric series are driven by full servo motors. Full servo motor drive replaces the traditional hydraulic drive, resulting in a 30%-50% reduction in energy consumption.