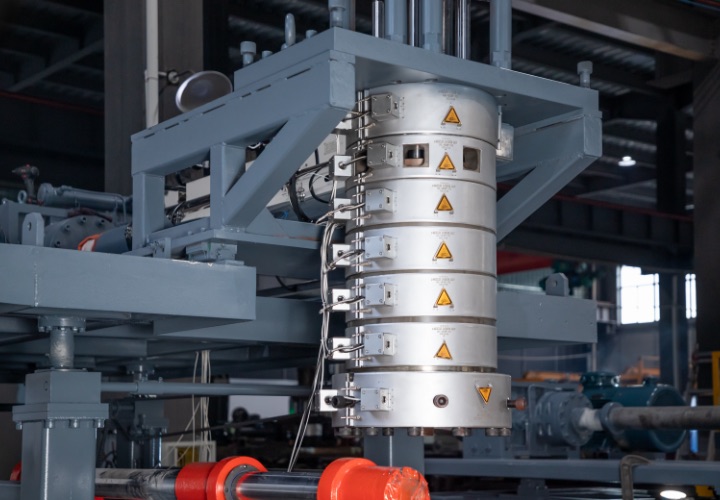

Starting from the screening of raw materials and components, we have specialized inspectors to track the manufacturing details of your production system. Our professional technicians have more than ten years of equipment debugging experience, ensuring that the machine you receive is ready for stable and efficient production.

The use of raw materials and components directly affects the later use of the equipment. In order to reduce the customer’s subsequent maintenance, all our components are selected from internationally renowned brands, such as Siemens, HOLIP, Northman, PHASE, SCHNEIDER, etc. In addition, when making base frames or die heads, we choose high-quality iron and do more processing to make them more durable.

With our dedicated inspection, you will receive a high-performance blow molding system that can meet your production needs. Before delivery, our professional technicians will test the machine to guarantee its stability and production efficiency. Also, we check through the end products to see if your product requirements are fulfilled.

In addition, some products will be sent to the research institute for testing, ensuring that the products are qualified and meet customer requirements. For example, pesticide packaging and industrial barrels will undergo a drop test and airtightness test, guaranteeing product qualification.