In the product design stage, our engineers will combine the experience of blow-molded furniture and your production requirements, and design a production line that meets your production needs. Blow-molded furniture parts are in high demand of solidity. In order to ensure the firmness of furniture or furniture components, we will perform tests like drop tests and pull tests on the samples. The qualified samples will be sent to you for final acceptance. Our Accumulator Head Series is recommended for the production of plastic tables, chairs, table legs and other furniture parts.

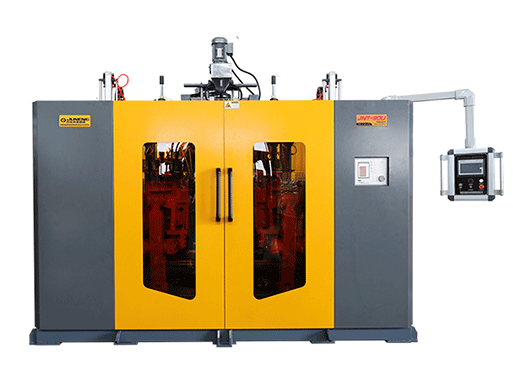

Accumulator Head blow molding machine adopts a full hydraulic drive and tie-rod type clamping mechanism. Configured with die head lifting platform and mold shifting device, servo motor, wall thickness control and robot arm.

Our C series is fully hydraulically driven. The clamping mechanism adopts the rod type.

JUNENG's U series is also fully hydraulically driven but adopts a toggle clamping unit for larger clamping force. It is equipped with a lifting platform to make mold changing more convenient.